The fixed hybrid prosthesis was developed by Professor Branemark and his colleagues and has had a very successful tract record. Patients with compromised mandibular bearing surfaces, for example those with moderate to severe resorption or retruded tongue positions and/or unfavorable floor of mouth contours benefit from the placement of implants and some of these patients prefer to be restored with a fixed prosthesis rather than an overdenture. The essential question that must be addressed in each case is whether a fixed prosthesis is in the best interest of the patient? This issue is addressed in detail as well as a detailed accounting of the methods of fabrication of these prostheses.

Implant Dentistry – Edentulous Mandible – Fixed Prostheses — Course Transcript

- 1. 5. Edentulous Mandible Fixed Prostheses John Beumer III DDS, MS Hiroaki Okabe CDT Division of Advanced Prosthodontics, Biomaterials and Hospital Dentistry, UCLAThis program of instruction is protected by copyright ©. No portion of thisprogram of instruction may be reproduced, recorded or transferred by anymeans electronic, digital, photographic, mechanical etc., or by anyinformation storage or retrieval system, without prior permission.

- 2. Fixed vs Removable Edentulous mandiblePatient selection and treatment planning based upon: ! Biomechanics ! Esthetic challenges ! Psychological demands ! Need for hygiene access ! Oralcompliance ! Quality of the soft tissues ! Cost

- 3. Implant Supported Fixed Prosthesis – MandibleImplant Biomechanics –Minimum requirements Length of implants ! Minimum length – 7 mm Number of implants ! Minimum number – 4 Anterior – Posterior (A-P) Spread ! Minimum amount – 1 cm

- 4. Implant Supported Prosthesis – MandibleMinimum requirements ! Length of implants ! Minimum length – 7 mm ! Number of implants ! Minimum number – 4 ! A-P Spread ! Minimum amount – 1 cm

- 5. Biomechanics and A-P spread! Only 4 implants have placed but the Anterior – Posterior spread is10 mm and is sufficient for a fixed prosthesis with cantilever extensions of up to 20 mm.

- 6. Biomechanics and A-P spread Unnecessary implants were placed in this patient! Implants are unnecessary posterior to the mental foramen in almost all patients unless the foramen are located so anteriorly that an appropriate A-P spread cannot be established.! If a fixed prosthesis is fabricated for this patients, it must be made in segments and designed to allow for flexure of the mandible during function.

- 7. Fixed Implant Supported Prosthesis – Mandible Anterior – Posterior Spread A-P Spread (1 cm or more) Cantilever LengthCantilever length should not exceed 2 timesthe A-P spread or a maximum of 20 mm.

- 8. Implant Supported Prosthesis – Mandible “

- 9. Biomechanics and A-P spreadInsufficient A-P spread combined with excessive cantilever lengthResult ! Mechanical failures ! Implant overload In this patient the result was recurrent fractures of the prosthesis retaining screws (arrows).

- 10. Implant Supported Prosthesis – ComplicationsInsufficient A-P spread combined with excessive cantilever length (34 mm on the left side and 26 mm on the right side) Result: ! Mechanical failure – Implant fracture ! Implant overloadIn this patient a combination of excessive cantilever length andinsufficient A-P spread lead to implant overload and a resorptiveremodeling response of the adjacent bone and implant fracture.

- 11. Implant Overload and Bone Resorption Possible Mechanisms of Implant Failure*! Excessive occlusal loads! Resulting microdamage (fractures, cracks, and delaminations [arrows])! Resorption remodeling response of bone is provoked! Increased porosity of bone in the interface zone secondary to remodeling! Vicious cycle of continued loading, more microdamage, more porosity until failure (Howshaw et al, 1995; Brunski et al, 2000; )

- 12. Biomechanics and A-P spreadEven though six implants have have been placed, A-P spreadis only about 5 mm. The cantilever extension must be limited to10 mm and this is insufficient to restore the posterior dentitionwith a fixed prosthesis. A-P Spread

- 13. Biomechanics and A-P spread A-P SpreadIn this example the A-P spread exceeds 10 mm. This is quitesufficient to restore the posterior dentition with a fixed prosthesis.

- 14. Biomechanics and A-P spread The A-P spread and the cantilever lengths were within the prescribed limits in this patient. When these limits are observed the success rates of implants supporting these restorations exceeds 95% and the mechanical failures are few.

- 15. Fixed vs Removable Edentulous mandiblePatient selection and treatment planning also based upon:! Esthetic challenges! Psychological demands! Need for hygiene access ! Oralcompliance ! Quality of the soft tissues! Cost

- 16. Fixed vs Removable EstheticsSome older patients, because of lack of muscle tonus,require the presence of a properly contoured dentureflange in order to establish proper contours of thelower lip and the corner of the mouth particularlyduring a high smile.

- 17. Fixed vs Removable EstheticsNote the poor contour of the lower lip and cornersof the mouth in this patient who was fitted with afixed hybrid prosthesis.

- 18. Fixed vs Removable Need for hygiene access when the implants emerge through poor quality mucosaSuch tissues are more difficult to maintain in a healthy conditionand when implants emerge through poorly keratinized unattachedmucosa removable overlay dentures are recommended becauseoral hygiene access is easier for the patient.

- 19. Fixed vs Removable Amount of Keratinized Attached Mucosa! Both these patients have little or no attached keratinized mucosa! Because of a lack of keratinized attached mucosa these patients would be best served with removable overlay dentures.! Oral hygiene procedures are much easier to perform when the implants are surrounded by keratinized attached mucosa.

- 20. Fixed vs Removable Amount of Keratinized Attached Mucosa! Thispatient presented with ample residual keratinized attached mucosa. Note that almost all of these implants have well formed gingival cuffs. If the patient is capable and willing to properly use the hygiene aids, fixed would be a suitable choice for this patient.

- 21. Fixed vs Removable Amount of Keratinized Attached Mucosa! The labial surfaces of these implants emerge through poorly keratinized unattached mucosa. The patient is elderly and has difficulty manipulating oral hygiene aids. Removable overlay dentures were therefore recommended.

- 22. Fixed vs Removable Oral Compliance! It is difficult to manipulate the hygiene aids used in patients with fixed edentulous bridges. If the patient has impaired vision or impaired motor skills, removable overdentures are recommended because of facilitated hygiene access.

- 23. Fixed vs Removable Oral Hygiene One week post delivery! Oral hygiene must be maintained meticulously. Otherwise chronic peri-implant gingival infections develop which can result in considerable morbidity.! Peri-implantitis is already beginning to develop on the patient on the right one week post delivery. Fixed was probably the wrong choice for this patient.

- 24. Infection an hypertrophy of peri- implant tissuesSecondary to a combination of:! Plaque! Poor quality peri-implant tissues

- 25. Implants in the Edentulous Mandible Common Problems! Severe resorption ! Buccal-lingual dimension most important. Less than 5-6 mm requires bone augmentation! Lack of attached keratinized tissue ! Hygiene compromised when the implants are surrounded by poorly keratinized unattached mucosa ! Palatal grafts are favored over skin grafts! Lack of interocclusal space ! Limits design choices ! Compromises prosthodontic procedures ! Commonly encountered when a patient still retains residual dentition in either the maxilla or mandible ! Seen in some recently edentulated patients

- 26. Severe ResorptionAnatomic Limitations Severely resorbed mandibular body a)Vertical height – less than 7 mm b)Buccal lingual dimension – less than 7 mm at the implant sitesMandibles that are smaller than the above are at risk for fractureduring or immediately after implant placement and should beaugmented with a bone graft.

- 27. Severe Resorption Anatomic Limitations! The mandible fractured through the right posterior implant site two weeks following implant placement.! Reconstruction with a bone graft prior to implant placement would have been a better choice for this patient.

- 28. Severe ResorptionMandibles that are smaller than the aboveare at risk for fracture during or immediatelyafter implant placement and should beaugmented with a bone graft. Courtesy Dr. H Davis

- 29. Lack of Keratinized Attached Tissue” Partial thickness flaps with apical repositioning” Palatal grafts are preferred over skin grafts

- 30. Soft Tissue Surgical Procedures Free palatal Grafts! Donor tissue is sized to recipient-site dimensions! A thick split-thickness graft approaching full thickness is preferred (1.25-1.75 mm) when abutment coverage is desired! Primary contraction is negligible with palatal grafts! Secondary contraction is rarely a problemCourtesy Dr. M. El Ghareeb

- 31. Soft Tissue Surgical Procedures Free palatal graft harvest: Donor site 4 weeks after surgery ! A uniform graft is harvested with sharp dissection ! Hemostasis is achieved with electrocautery ! The donor site is dressed with absorbable collagen ! A palatal stent or a soft lined maxillary complete denture is provided to protect site & improve patient comfort.Courtesy Dr. M. El Ghareeb

- 32. Soft Tissue Surgical Procedures Free palatal graft Atrophic MN with thin Creation of a uniform periosteal band of attached ST recipient site Immobilization of graft One week postoperative: at recipient site Superficial epithelial sloughing & initial revascularizationCourtesy Dr. M. El Ghareeb

- 33. Lack of interocclusal space! Recently edentulated patients! Patients to be fitted with an immediate denture followed by an implant supported fixed edentulous bridge! Patients with supereruption of anterior teeth prior to extractionNote the supereruption of themandibular teeth. When these teeth are removed an aggressive alveolectomy needs to be performed prior to placement of implants.

- 34. Interocclusal spaceMinimum amount -15 mm from the head of the implant to theplane of occlusion in order to design an appliance with bothhygiene access and sufficient strength and rigidity to withstandthe rigors of mastication. 15 mm

- 35. Interocclusal space! Thereshould be sufficient space between the bottom of the bridge and the gingival tissues for proxy brush access between the implants.

- 36. Interocclusal space Insufficient hygiene accessThere is insufficient space for proper hygieneaccess. The risk of peri-implantitis and tissuehypertrophy will be substantial in this patient.

- 37. Ensuring properimplant position and angulation Surgical templates Existing dentures, if they are of appropriate contour and tooth position, can be duplicated to make effective surgical templates.

- 38. Role of Trial dentures! Trialdentures are made when the teeth of existing dentures are improperly positioned.

- 39. Proper implant Position and Angulation! Implants should be positioned so their screwaccess channels exit through the cingulum regionof the anterior teeth.! They should be angled so they are perpendicularto the plane of occlusion. Why ?

- 40. Proper implant Position and Angulation! Linguallyinclined implants existing through the tissues of the floor of the mouth are unusable and must be buried. Why? ! Theconstant movement of the floor of mouth tissues around the implants leads to uncontrollable tissue irritation

- 41. Proper implant Position and Angulation! Labiallyinclined implants are a significant problem for the prosthodontist and lab technician. Why? ! Theyrequire the fabrication of custom substructures adding significant complexity and cost to the prosthesis.

- 42. Soft Tissue Surgical Procedures at the Time of Second Stage Surgery Partial thickness flap with apical repositioning:! Can be utilized to increase Narrow zone zone of attached tissue with of keratinized mucosa limitations secondary to contracture! Apical repositioned flaps are sutured to the periosteum Sharp supra-periosteal (arrows) dissection! A soft lined CD is provided to protect site, improve patient comfort & minimize relapse Partial thickness flap Is apically repositioned & sutured to periosteumCourtesy Dr. M. El Ghareeb

- 43. Tissue Management! Whether a one stage or two stage surgical procedure is used closure should be designed to surround the implants with keratinized attached tissue.! Peri-implant tissues must be thinned as necessary in order to minimize peri-implant pocket depths.

- 44. Healing Period! The denture surfaces overlying the surgical sites are aggressively relieved! A temporary denture reliner is used to reline the denture in this area

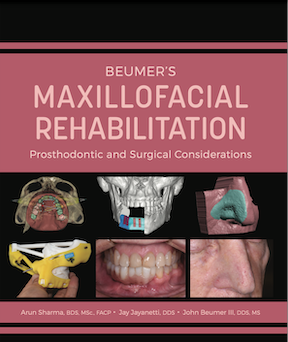

- 45. Fixed Implant Prostheses Treatment Choices! Two types ! PFM Fixed ! Fixed hybrid prosthesis

- 46. Fixed Prosthesis Options Porcelain fused to metal prosthesisAdvantages! Excellent esthetics! Nonporous materials! Little or no wear of occlusal surfacesDisadvantages! Expensive to fabricate! Time consuming! Requires a high level of technical expertise! Prone to cracks and fractures which are difficult and time consuming to repair.

- 47. Fixed Prosthesis Options Fixed hybrid prosthesisComponents! Cast metal framework! Acrylic resin! Denture teeth

- 48. Fixed Prosthesis Options Fixed hybrid prosthesisAdvantages! Less costly! Easier technically to fabricate! Easier to maintain and repair Disadvantages ! The acrylic resin retaining the denture teeth is porous and will absorb bacteria and odors ! Wear of the denture teeth ! Wear and deterioration of the pink acrylic resin

- 49. Fixed Prosthesis Options PFM vs Fixed Hybrid ProsthesisWe prefer the fixed hybrid prosthesis ! Less costly ! Easier to fabricate ! Easier to maintain and repair Fixed Hybrid Prosthesis PFM prosthesis

- 50. ImpressionsTwo techniques ! Use a pickup type impression copings with linked copings and a master impression tray ! Use transfer type copings with a stock tray and a silicone impression material

- 51. Master Impressions using transfer type (closed tray) impression copings with a stock tray ! Transfer type impression copings have been secured to the implant fixtures. A variety of shapes are available.! A stock tray designed to make impressions for partiallyedentulous patients, (shown above), can be used to make thistype impression. Note that in the anterior region of the tray isdeveloped to accommodate the height of the impression copings.

- 52. Master Impressions using transfer type (closed tray) impression copings with a stock tray! Before placing the impression copings into position theyshould be carefully inspected. If imperfections are discoveredthey should not be used for master impressions.! Be careful not to entrap tissue between the coping and theimplant fixture.! A polysiloxane impression material with sufficient rigiditymust be used

- 53. Master Impressions using transfer type (closed tray) impression copings with a stock tray! The impression is removed and inspected. The retromolar pad must be recorded in the impression.! The transfer type impression copings are removed from the patient and attached to implant fixture analogues.! The impression coping – fixture analogue units are then placed into the impression as shown above.! The impression is boxed as shown previously and poured with improved dental stone using the manufacturer s specifications regarding water powder ratios

- 54. Making the master cast! A separating medium is applied to the silicone impression to prevent the Gingitech from adhering to the impression material.! The joint between the fixture analogue and the Impression coping is covered completely with the Gingitech material.! The impression is then boxed and poured with improved dental stone.

- 55. Master Impressions – Linked copings technique using pick-up (open tray) impression copings Transfer impressionStock tray Preliminary Impressions are coping made with transfer type (closed tray) impression copings and a stock tray The healing abutments are removed and replaced with transfer type impression copings

- 56. Master Impressions – Linked copings technique using pick-up (open tray) impression copings Transfer impression copings are connected to implant fixture analogues and placed into the impression

- 57. Master Impressions – Linked copings techniqueusing pick-up (open tray) impression copings! Beforeuse carefully inspect the undersurface of the impression copings (arrow). If any imperfections are noted they should not be discardedImpression copings are secured to the fixture analoguesimbedded in the preliminary cast with long guide pins

- 58. Master Impressions – Linked copings technique using pick-up (open tray) impression copings ! Pick–up type (closed tray) impression copings are screwed onto the analogues embedded in the cast ! Dental floss is used to connect the impression copings ! Auto polymerizing acrylic resin is used to connect the copings

- 59. Master Impressions – Linked copings technique using pick-up (open tray) impression copings! The copings are separated from on another with a thin separating disc! The impression copings are blocked out wax! The impression tray is made. Note that the tray extends to record the retromolar pad for this area must be recorded in the impression

- 60. Master Impressions – Linked copings technique using pick-up (open tray) impression copings! Impression copings are connected together with either cyanoacrylate or a pattern resin. In this patient cyanoacrylate was used.

- 61. Master Impressions – Linked copings technique using pick-up (open tray) impression copings! In this patient pattern resin was used to connect the impression copings

- 62. Master Impressions – Linked copings technique using pick-up (open tray) impression copings Pick-u! The master impression tray is tried in to insure it seats easily and in the proper manner. The guide pins should project through the top of the tray. Sometimes the holes for the guide pins need to be enlarged! The impression is made with an elastic impression material

- 63. Master Impressions – Linked copings technique using pick-up (closed tray) impression copings Pick-u! Note that the retromolar pad is recorded in the impression. Why? ! The retromolar pad is one of the anatomic land marks used to determine the proper plane of occlusion! The connected impression copings are embedded as one unit ensuring that they will accurately record the position and angulation of the implants in the master cast.

- 64. Master Impressions – Linked copings technique using pick-up (open tray) impression copings! ! Boxing the master impression. The land of the cast should be 4-6 mm wide.! The impression is boxed as shown previously and poured with improved dental stone using the manufacturer s specifications regarding water powder ratios

- 65. Master cast with fixture analogues imbedded! Note that the retromolar pads (ovals) were recorded in theimpression. These are important landmarks in determining theplane of occlusion.! The land of the cast should be at least 4 mm wide. This willlater be used to retain a silicone template.

- 66. Record Bases The cast undercuts and those around the healing abutments, are blocked out with wax, separating medium is applied and the record base completed with tray resin.

- 67. Facebow transfer record! Afacebow transfer record is made and the upper master cast transferred articulator.

- 68. Facebow transfer record! Remove the facebow from the patient. Insert the maxillary cast into the record on the bite fork and attach the cast and face bow to the articulator with the jig.

- 69. Design of Record Bases! Record bases should cover the retromolar pad.! The labial flange should be shorted in order to more truly represent the contours of the final prosthesis.

- 70. Design of Record Bases

- 71. Centric Relation Records! VDO and centric relation records are made in a customary fashion

- 72. Centric Relation Records ! Mount the lower cast with the centric relation record

- 73. OcclusionIf opposed by complete denture ! Bilateral balanced occlusionIf opposed by implant assisted overlay denture ! Bilateral balanced occlusionIf opposed by implant supported prosthesis ! Group function (Mutually protected occlusion) or ! Anterior guidanceIf opposed by natural dentition ! Group function (Mutually protected occlusion) or ! Anterior guidance

- 74. Trial Denture ! ! ! ! Refine anterior esthetics

- 75. Protrusive records

- 76. Fabricating the Metal FrameworkA silicone template is made using a silicone putty

- 77. Fabricating the Metal Framework Labial-buccal silicone matrix techniqueThe anterior teeth are removed from the record baseand attached to the silicone template. A small amountof sticky wax will help connect the denture teeth to thetemplate.

- 78. Fabricating the Metal Framework Labial-buccal silicone matrix! The matrix is designed to be removed in segments while developing the contours of the metal framework.

- 79. Metal framework design and fabrication Fixed hybrid prosthesis

- 80. Fixed Prosthesis Options Fixed hybrid prosthesisComponents! Cast metal framework! Acrylic resin! Denture teeth

- 81. Basic design guidelines – Metal framework1. Cantilever extension should not exceed two times A-P spread or 20 mm2. When possible the screw access holes should be through metal3. Narrow labial lingual thickness anteriorly4. Proxy brush access between implants

- 82. Basic design guidelines – Metal framework5. The cantilever extension should be designed to minimize food impaction .6. Metal – acrylic resin finish line on the lingual side of the distal implants should be 4-6 mm in height.7. In cross section, the undersurface of all portions of the framework must be convex.8. Provide sufficient retention for acrylic resin.

- 83. Basic design guidelines – Metal framework Why ? Implant overload and bone loss Mechanical failures

- 84. Biomechanics and A-P spread Insufficient A-P spread combined with excessive cantilever lengthResult ! Mechanical failures ! Implant overload In this patient the result was recurrent fractures of the prosthesis retaining screws (arrows).

- 85. Implant Supported Prosthesis – ComplicationsInsufficient A-P spread combined with excessive cantilever length (34 mm on the left side and 26 mm on the right side) Result: ! Mechanical failure – Implant fracture ! Implant overloadIn these patients a combination of excessive cantilever length and insufficientA-P spread lead to implant overload and a resorptive remodeling response ofthe adjacent bone and implant fracture and implant failure.

- 86. Basic design guidelines – Metal frameworkCantilever length ! Not to exceed two times A-P spread to a maximum of 20 mm.

- 87. Basic design guidelines – Metal framework2. When possible the screw access holes should be through metal. Why ? When screw access channels are in acrylic resin, the resin tends to craze and crack over time, resulting in loosening of teeth, facilitating microleakage and eventual detachment of the resin from the metal framework.

- 88. Basic design guidelines – Metal framework3. Narrow the labial lingual thickness anteriorly. Why ? To facilitate hygiene access.

- 89. Basic design guidelines – Metal framework 4. Proxy brush access between implants. Why ?To facilitate oral hygiene access to the prosthesisbetween the implants and the undersurface of theprosthesis.

- 90. Basic design guidelines – Metal framework5. The cantilever extension should be of one of two designs: ! 4 mm above the alveolar ridge. (original Branemark design) ! In contact with the posterior alveolar ridge with proxy brush access just posterior to the distal implant. .

- 91. Basic design guidelines – Metal framework6. Metal – acrylic resin finish line on the lingual sideof the distal implants should be 4-6 mm in height.

- 92. Basic design guidelines – Metal framework Fracture of the metal framework Insufficient vertical height of metal on the lingual side led to fracture of the cantilever extension 2years after delivery.

- 93. Basic design guidelines – Metal framework7. In cross section, the undersurface of all portions of the framework must be convex. Why ?To enable proper hygiene access. Concavities on the underside of the prosthesis are difficult to clean. Dental plague willaccumulate in these areas which leads to tissue irritation andhypertrophy.

- 94. Basic design guidelines – Metal framework8. Provide sufficient retention for acrylic resin. Why ? To prevent separation of the acrylic resin from the metal framework. Loop and struts are preferred to bead retention.

- 95. Basic design guidelines – Metal framework Separation of acrylic resin from the metal framework! !

- 96. Prevention of Microleakage between the metal framework and the acrylic resin! !

- 97. Basic design guidelines – Metal framework Summary ! No concave under surfaces ! Screw access holes in metal when possible ! Proxy brush access ! Retention for acrylic resin ! High lingual finish line for strength and rigidity ! Limit cantilever to 2 times A-P spread but no more than 20 mm. ! Cantilever extension 3-4 mm above the tissue

- 98. Cast Frameworks! Wax pattern! Burnout! Cast and finish! Section/Solder if necessary Metals used: ! Gold palladium ! Silver palladium ! Type III gold

- 99. Verifying the fit of the metal framework! If transmucosal abutments are used fit can be checked visually! If the framework is designed to engage the implant fixtures, fit is determined by touch and feel.! X-rays can also be used but they must be taken a right angles to the long axis of the implant

- 100. Finishing the prosthesis! The denture teeth are attached to the metal framework and the occlusion refined depending upon the status of the opposing arch.! Since the opposing arch has been restored with a fixed implant supported prosthesis, the occlusion will be group function.

- 101. Occlusion (Based on weakest arch)If opposed by complete denture ! Bilateral balanced occlusionIf opposed by implant assisted overlay denture ! Bilateral balanced occlusionIf opposed by implant supported prosthesis ! Group function (Mutually protected occlusion) or ! Anterior guidanceIf opposed by natural dentition ! Group function (Mutually protected occlusion) or ! Anterior guidance

- 102. Final Try In AppointmentThe occlusion is fine tuned and the trial prosthesesare tried in one last time. During this appointment:! Verifyrecords! Obtain final esthetic approval from the patient

- 103. Preparing for flasking! Screw access holes that exit the posterior dentition should be prepared so as to minimize the destruction of the occlusal surfaces. !

- 104. Flasking! Attach fixture analogues to the bottom of the metal framework

- 105. Flasking! Theprosthesis has been flasked. In one side is the metal framework and in the other are imbedded the denture teeth.

- 106. FlaskingThe framework is removed from the cast, a metalbonding agent is applied followed by a layer of opaque.

- 107. Finishing the prosthesisFollowing processing of the heat cure acrylic resinthe prosthesis is carefully finished and polished.

- 108. Clinical remount and equilibrationIn this patient the maxilla was restored with animplant assisted overdenture. Therefore theocclusal scheme was bilateral balance.

- 109. Delivery Completed prosthesis ! Secured with gold alloy screws ! Note hygiene access ! Occlusion ! Anterior guidance with centric only contact posteriorly ! Refined with a clinical remount

- 110. CAD – CAM Frameworks! The pattern is developed in the usual way! A laser scans the shape of the plastic pattern into a computer. Courtesy Dr. S. Lewis Courtesy Dr. S. Lewis

- 111. CAD – CAM Frameworks! With all the data collected, the milling procedure is performed in one solid block of titanium. Courtesy Dr. S. Lewis Courtesy Dr. S. Lewis

- 112. CAD – CAM FrameworksCompleted framework. Note the design criteria are thesame. Courtesy Dr. S. Lewis Courtesy Dr. S. Lewis

- 113. Titanium vs Zirconium Frameworks Zirconium Frameworks ! Not recommended because the blocks from which they are milled exhibit flaws and as a result these frameworks are more prone to fracture. Courtesy Dr. S. LewisTitanium Frameworks! Strong! Precise! Light-weight

- 114. Basic design guidelines – Metal framework! Beware of metal frameworks designed by the implant companies.! It is the responsibility of the restorative dentist to design the metal framework

- 115. Angulation Issues Labially inclined implantsSolution: Custom substructures with the prosthesisretained with lingual set screwsCustom substructures are milled to a 3 degree taper.

- 116. Angulation IssuesCustom substructures with the prosthesis retained with lingual set screws Metal Substructure engaged via lingual set screws

- 117. Fabrication of the metal framework Custom substructures with the prosthesis retained with lingual set screws! Pattern resin is flowed over the customized substructures and shaped appropriately.! Note the development of the screw access channels for the lingual set screws

- 118. Fabrication of the metal framework Custom substructures with the prosthesis retained with lingual set screwsFull contour wax pattern with denture teethNote: Proxy brush access

- 119. Fabrication of the metal frameworkCustom substructures with the prosthesis retained with lingual set screwsFull contour wax pattern with denture teethNote: Lingual set screws used to retainthe prosthesis

- 120. Fabrication of the metal frameworkCustom substructures with the prosthesis retained with lingual set screwsDenture teeth are removed and the wax pattern is cutback creating sufficient space for the acrylic resin.Note:! Hygiene access! Lingual set screws for retaining the prosthesis

- 121. Fabrication of the metal framework Custom substructures with the prosthesis retained with lingual set screwsFinished metal framework ! It should fit precisely onto the custom substructures ! It is retained by lingual set screws as shown

- 122. Completing the prosthesisCustom substructures with the prosthesis retained with lingual set screws ! The denture teeth are attached to the metal framework with wax with the help of the silicone template. ! The occlusion is then reestablished.

- 123. Completed ProsthesisCustom substructures with the prosthesis retained with lingual set screws

- 124. Labially Inclined ImplantsCustom substructures with the prosthesis retained with lingual set screwsCustom substructures are screwed to the implantfixtures with gold alloy abutment screws.

- 125. Labially Inclined ImplantsCustom substructures with the prosthesis retained with lingual set screwsFixed hybrid prosthesis issecured to the customsubstructures with lingualset screws.

- 126. Angulation IssuesCustom substructures with lingual set screwsCompleted prosthesis! Note hygiene access! Occlusion ! Anterior guidance with centric only contact posteriorly ! Refined with a clinical remount

- 127. Angulation IssuesCustom substructures with lingual set screws ! Another patient with labially inclined implants. ! Silicone matrix made of the denture set up. ! The substructure is contoured to be compatible with the position of the denture teeth.

- 128. Angulation IssuesCustom substructures with lingual set screws ! Completed custom substructure ! Note that the patient s class III jaw relation combined with slight labial implant angulation required the fabrication of the customized substructure.

- 129. Angulation Issues Custom substructures with lingual set screws! Metal framework is secured to custom substructure with lingual set screws

- 130. Angulation Issues Custom substructures with lingual set screws! Completed restoration

- 131. Fabrication of PFM Fixed Prostheses for the Edentulous Mandible

- 132. Fabrication of PFM Fixed Prostheses ! Complete and verify trial denture setup ! Secure UCLA abutments with resin cylinders to the fixture analogues and connect them together with pattern resin

- 133. Fabrication of PFM Fixed Prostheses ! Make silicone matrix of the denture setup ! Secure silicone matrix to the master cast and flow wax into the matrix

- 134. Fabrication of PFM Fixed Prostheses ! Refine wax pattern ! Refine the occlusion ! Note the hygiene access

- 135. Basic contours – PFM Fixed edentulous bridge! Reduced labial lingual dimension for easy hygiene access on the lingual side.! Limit cantilever to 2 times A-P spread but no more than 20 mm.! High lingual finish line of metal for strength and rigidity! Cantilever extension 3-4 mm above the tissue! Screw access holes in metal when possible! Proxy brush access for hygiene! No concave under surfaces

- 136. Basic contours – PFM Fixed edentulous bridge! Cut back of wax pattern prior to casting

- 137. Basic contours – PFM Fixed edentulous bridge One piece casting fits the master cast perfectly. Note the contours of the undersurface and the buccal lingual dimension.

- 138. Basic contours – PFM Fixed edentulous bridge The fit of the casting is verified intra-orally. Method: ! Feel ! X-rays at right angles

- 139. Basic contours – PFM Fixed edentulous bridgeOcclusal surfaces – Metal or porcelain:! Dependent upon the opposing occlusion

- 140. Completed maxillary prosthesis! Opposing arch is restored with an overdenture with resin denture teeth.

- 141. Completed Prostheses Occlusal surfaces Porcelain because the prosthesis is opposing a complete denture with resin denture teeth

- 142. Basic design guidelines – Metal framework

- 143. Basic design guidelines – Metal framework! ! !

- 144. Basic design guidelines – Metal framework ! The prosthesis was remade and the metal framework strengthened to prevent flexure ! Opposing arch was natural dentition so metal surfaces were used.