The chemistry and clinical characteristics of the dental cements most commonly employed today (Zinc oxide and eugenol, Zinc phosphate, Polycarboxylate, Glass ionomer, Resin-modified glass ionomer, Resin, Calcium aluminate) are described in detail in this presentation. Clinical procedures performed during cementation of individual crowns and fixed dental prostheses are illustrated. Complications associated with retained cement subgingivally are described, particularly those associated with cement retained around implant crowns.

Transcript

- 1. Dental cements & cementation procedures Charles J. Goodacre, DDS, MSD Professor of Restorative Dentistry Loma Linda University School of Dentistry This program of instruction is protected by copyright ©. No portion of this program of instruction may be reproduced, recorded or transferred by any means electronic, digital, photographic, mechanical etc., or by any information storage or retrieval system, without prior permission.

- 2. Provisional Cements • They are typically zinc oxide powder or zinc oxide paste mixed with eugenol liquid • Noneugenol formulations are available that do not soften resin (as in provisional crown). They use carboxylic acids in place of eugenol • The liquid can be ethoxybenzoic acid, known as ZOEBA, making it stronger • TempBond Clear is a translucent cement with Triclosan (an antibacterial & antifungal agent)

- 3. The Hardening of Dental Cements & Constituents • There are 2 hardening mechanisms of dental cements 1) Acid-base reactions 2) Polymerization reactions • Acid-Base Reaction cements use one of three powders & one of three liquids • Polymerization Reaction cements use a composite resin (resin matrix with filler particles) that is polymerized by light, chemicals, or a combination of both (dual)

- 4. Zinc Phosphate Cement • Powder 90% zinc oxide 10% magnesium oxide • Liquid 2/3rds Phosphoric acid 1/3rd Water & aluminum phosphate (water is critical as it controls rate of reaction) • Hardened cement is undissolved powder particles in matrix of zinc aluminophosphate compound

- 5. Characteristics of Zinc Phosphate Cement • Higher solubility than other cements except for Polycarboxylate that has a comparable solubility • Postcementation sensitivity can occur • No fluoride release • No adhesion • Incremental, slow mixing required • Good marginal fit minimizes the exposure of the cement to oral fluids and has negated this potential disadvantage for decades • Acid penetration of dentin tubules causes short – term sensitivity for some patients • For patients with high caries potential, the cement does not help protect the tooth from caries • Retention provided mechanically • Reaction heat needs dissipation

- 6. Zinc Phosphate Mixing • Dispense powder & 5-6 drops of liquid • Incremental mixing for 15-20 seconds per increment • 1.5 – 2 minutes total mixing time

- 7. Advantages of Zinc Phosphate • Longest record of very effective and successful use • Increased working time may be beneficial when cementing multiple single units or a long – span fixed prosthesis with multiple retainers • Zinc phosphate cement appears to be the least technique sensitive cement and has been successfully used by thousands of clinicians with varying degrees of meticulousness for decades Anusavice, 1989

- 8. Polycarboxylate Cement • Powder (like zinc phosphate) Zinc oxide & Mg or Sn oxide Stannous fluoride to ↑ strength and improve handling – not a source of fluoride release • Liquid Polyacrylic acid or copolymer of acrylic acid (carboxylic, itaconic). Some brands have the acid freeze dried and placed in powder with liquid being water • Hardened cement is undissolved powder particles in an amorphous gel matrix

- 9. Characteristics of Polycarboxylate Cement • Biocompatability (kind to pulp) • Adhesion • Short mixing time (30 seconds) • Short working time (1.75 – 2.5 minutes) • Good for use with sensitive teeth • Good for base• Retention to tooth structure and decreased microleakage • Good for blocking out undercuts • Mix quickly to obtain adhesion • Apply rapidly to crown and seat • Not well suited for cementing several crowns at one time

- 10. Polycarboxylate Mixing • Dispense measured amount of powder & liquid • Bulk mixing by incorporating all powder into liquid at one time • 30 seconds maximum mixing time • Mixing too thick and loss of gloss prevents adhesion and complete seating

- 11. Polycarboxylate Adhesion • There is chemical adhesion to the tooth by the polyacrylic acid liquid reacting with the calcium of the hard tooth structure. May also produce a weaker bond to the collagen of the dentin Smith, 1968

- 12. Polycarboxylate Adhesion • To achieve adhesion, the cement should be mixed rapidly (30 seconds maximum) and the restoration seated before the cement loses it surface gloss (so some polyacrylic acid liquid is still available for interaction with the tooth when the cement comes into contact with the tooth) Phillips, 1991

- 13. Polycarboxylate Adhesion • To insure interaction between the tooth and cement, the tooth surface should be cleaned to remove the smear layer using a 20% polyacrylic acid solution (GC Cavity Conditioner or Ketac Conditioner) for 10 seconds followed by water rinsing Smear Layer

- 14. Polycarboxylate Adhesion To Crown Can Be A Problem • There were early failures where the crown came loose from the cement • The metal surface must be clean to achieve a bond with carboxylate cement • Airborne particle abrasion is the preferred method for achieving a clean surface that will interact with the cement Ady and Fairhurst, 1973

- 15. Glass Ionomer Cement • Powder (Ca, Fl, Al, SiO2) Calcium fluoroaluminosilicate glass • Liquid Originally polyacrylic acid but now most use copolymer of acrylic acid (itaconic, maleic, or tricarboxylic). Some brands have the acid freeze dried and placed in the powder with the liquid being water • Hardened cement composed of undissolved powder in polysilicate gel matrix of Ca & Al salts

- 16. Characteristics of Glass Ionomer Cement • Fluoride release • Adhesion • Somewhat short mixing time (45 seconds maximum when mixed by hand) • Early moisture sensitivity • Long time to reach full strength (several days) • Good for patients with a history of caries experience • Good for prepared teeth with dark but hard dentin areas (previously decalcified areas) • Retention to tooth structure and decreased microleakage • Apply to crown and seat fairly rapidly • Protect margins with resin glaze • No vigorous chewing right away

- 17. Glass Ionomer Adhesion • There is chemical adhesion to the tooth by the polyacrylic acid liquid reacting with the calcium in the apatite. Mechanism comparable to polycarboxylate cement • A 20% polyacrylic acid liquid should be used to condition the tooth surface (remove smear like) like polycarboxylate

- 18. Glass Ionomer Mixing • Measured amount of powder to specified number of drops of liquid • Bulk mixing in 2 increments (20 seconds total mixing) • Maximum mixing time of 45-60 seconds

- 19. Fluoride Release & Caries • GI releases fluoride • There is Fl update in the underlying dentin • Fl release influences Fl concentration of adjacent teeth • Adjacent carious lesions were significantly reduced

- 20. Resin-Modified Glass Ionomer Cement • Powder (Ca, Fl, Al, SiO2) Calcium fluoro-alumino-silicate glass and initiators for light and chemical polymerization • Liquid (solution of hydrophilic monomers) Polyacrylic acid and a hydrophilic (water soluble) monomer such as HEMA (hydroxyethyl methacrylate) • Light-activated resin polymerization precedes formation of the polysilicate gel matrix

- 21. Characteristics of Resin Modified Glass Ionomer • Fluoride release • Adhesion • Somewhat thick when mixed • Reduced early moisture sensitivity • Good early strength • Expands upon setting • Good for patients with a history of caries experience • Good for prepared teeth with dark but hard dentin areas (previously decalcified areas) • Retention to tooth structure and decreased microleakage• Not well suited for cementing several crowns at one time or a long span multi – abutment fixed prosthesis • Marginal cement not as susceptible to early dissolution because of resin content. No need to coat margins • Resin present in cement enhances early strength and resistance to early dislodgment. Excess should be removed before it is completely hardened. Hardened excess requires scaler to remove. • Original problem with all – ceramic crown fracture and posts fracturing teeth seems to be resolved by lower expansion

- 22. Resin Modified Glass Ionomer Mixing

- 23. Resin Cement • Similar to composite resins (most use a resin matrix of bis-GMA; UDMA; and TEGDMA with silane- treated inorganic fillers (silica, glass, or colloidal silica) • Most resin cements require an adhesive monomer (dentin bonding agent) such as HEMA, 4-META, and MDP. HEMA & MDP are present in the dentin bonding agent & the resin cement. 4-META does not require a separate bonding agent

- 24. Resin Cement • Resin cements can be polymerized chemically, by light, or by using a dual polymerization process • With chemical polymerization, 2 pastes are mixed together that contain BP initiator (benzoyl peroxide) & amine activator (N-dimethyl-p-toluidine). Amine reacts with BP to form free radicals & initiate polymerization • Light polymerization uses a single paste system. Light causes the photosensitizer CQ (camphorquinone) to interact with the amine DMAEMA (dimethylaminoethyl methacrylate) to form free radicals & initiate polymerization

- 25. Characteristics of Resin Cements • Not soluble • Adhesion (micromechanical) • Multiple colors available • Extended working time for light polymerized and dual polymerized • Increased retention? • Increased all – ceramic crown strength • Fluid / moisture control is critical • Requires meticulous attention to protocol to achieve bonding

- 26. Calcium Aluminate Cement • Powder Calcium aluminate & some glass ionomer components added to improve handling (GI components are not identifed) • Liquid Water

- 27. Characteristics of Calcium Aluminate Cement • Nano crystals (hydroxyapatite) form on the surface of the tooth & crown that seal the interface • Bonds to the tooth using the same principle as remineralization • Fluoride released initially • No hydraulic pressure resistance • Does not produce pulpal inflammation

- 28. Calcium Aluminate Mixing • Place capsule in activator and press handle down for 3 seconds • Mix 8-10 seconds at 4 to 5,000 rpm • Insert mixed capsule into applicator and express mixed cement into crown • Stabilize for 2 minutes until rubbery, then remove excess, let set an additional 4 minutesApplicator Activator

- 29. CLINICAL PROCEDURES

- 30. Removal of Provisional Crown • Spoon excavator placed carefully under margin of provisional restoration so as not to damage finish line on tooth (careFUL, careFUL, careFUL) • Use a spoon excavator to engage axial resin occlusal to the margin • Hemostats used carefully so as not to exert excess lateral leverage on teeth

- 31. Provisional Cement Removal & Preparing The Tooth Surface for Definitive Cementation • Clean the tooth mechanically or chemically • Mechanical cleaning using hand instruments, cotton pellets, disposable applicators, pumice • Chemical cleaning using saliva, acids, or special agents such as degreasers, dentin desensitizers, antimicrobials

- 32. • Polyacrylic acid liquid (20% PAA) is used with Polycarboxylate and GI cements (10 second application) to remove the smear layer without opening the dentinal tubules • Phosphoric acid is used to etch the tooth surface in preparation for use of a resin cement (other than self-etching cements) Provisional Cement Removal & Preparing The Tooth Surface for Definitive Cementation (con’t)

- 33. Clinical Trial Placement & Adjustment • All residual provisional cement must be removed (requires drying & examining) • Adjust proximal contacts first (which one is heavy?) • Occlusal adjustments are made after proximal contacts are correct and the crown is fully seated

- 34. Which Proximal Contact is Heavy? • Proximal contact resistance to floss • Burnishing of metal or articulating film (mylar) / ribbon for contact location • Shim stock is most accurate for presence or absence of contact • Patient’s perception of pressure in front of or behind crown • Marginal fit on mesial versus distal

- 35. Marginal Finishing • Improves smoothness and transition zone of good fitting crowns / inlays • It doesn’t enhance crowns that “fit like socks on a rooster” • Fine grit rotary instruments and abrasive discs / rubber points • Can be accomplished both before and after cementation Courtesy of Richard Tucker & Frederick Westgate

- 36. Marginal Finishing • Soflex discs • Green stone / white stone shaped as needed or fine grit diamonds rotated slowly from crown to tooth • Pumice

- 37. Marginal Finishing Tooth extending beyond crown Crown extending beyond tooth Learn to Use Light Reflections Across the Margin

- 38. Marginal Finishing

- 39. Occlusal Adjustment • With multiple crowns, it is best to adjust them one at a time, making sure the occlusion on other teeth is the same after each crown is adjusted as it was before the crown was placed

- 40. Achieving Complete Seating During Cementation • Finger pressure (use with anterior crowns, all – ceramic crowns, and posts and cores) • Use patient’s musculature by having them bite on a wooden stick or peg

- 41. Achieving Complete Seating • Use a rocking motion or 360 degree rotation of wooden stick after crown appears to be fully seated A horizontal and vertical rocking motion of the loaded wooden stick for 30 seconds decreased the vertical seating discrepancy by a mean of 203 micrometers Rosenstiel, J Am Dent Assoc 1988;117:845-848

- 42. Verifying Complete Seating During Cementation • Marginal fit through cement • When margin is visible, wipe away excess and see if additional pressure expresses more cement

- 43. Verifying Complete Seating

- 44. Isolation During Setting of the Cement

- 45. GI Cement Protection While Setting • Glass Ionomer should be coated with a “resin bonding agent” or “resin glaze” while it is hardening • Apply the coating over the marginal excess and light polymerize it • Recoat the margins with resin after the cement has hardened and the marginal excess has been removed

- 46. Stabilization During Setting FINGER PRESSURE HAVE PATIENT BITE ON COTTON ROLLS

- 47. Cement Removal • Explorer & Floss (effective for hardened brittle cements like zinc phosphate) • Explorer & Floss can also be used with partially polymerized Resin / Resin Modified Glass Ionomer cements. Use brief light exposure (2 seconds), remove excess, then completely polymerize • Scaler (required for hardened Glass Ionomer, Resin – Modified GI, and Resin that has set completely

- 48. Cementation of Crowns on Dental Implants • Many, if not most, of the crowns that attach to dental implants are being cemented rather than being screw retained • This process can produce substantial complications

- 49. Fistulas Associated With Dental Implants • 117 of 11,764 implants affected • Mean of 1% • Initially, they were associated with loose abutment screws but new causes have emerged 1%

- 50. With many implant crowns being cemented, we are now seeing fistulas and adverse responses from retained cement Cementation of Crowns on Dental Implants

- 51. Excess Marginal Cement Is An Emerging Problem • A documented cause of peri-implant disease Pauletto, 1999; Gapski, 2008 • If the excess can be removed, the problem is resolved for most patients • It can take several years before the excess cement causes disease Thomas, J Periodontol 2009;80:1388-92 6-30-2011

- 52. Peri-Implant Disease • “If peri-implant disease in the form of peri-mucositis or peri-implantitis is seen to develop around the tissues of a cement retained implant restoration then excess cement must be considered as a potential etiologic factor Wadhwani, 2011 6-30-2011

- 53. Examples of Adverse Soft Tissue Responses to Retained Cement Caught Early and Corrected but it Produced Pain and Required Professional Treatment

- 54. Example 1

- 55. Example 2 Courtesy of Dr. Joseph Kan

- 56. 4 months postcementation, surgical exposure of inflammatory site Example 3 Courtesy of Dr. Chandur Wadhwani

- 57. Courtesy of Dr. Chandur Wadhwani

- 58. Bone Loss Requiring Surgery & Bone Grafting to Save Implant

- 59. Implant placement: 2/14/07 Restored: 8/5/08 5/20/09 Example 1 Courtesy of Dr. Chandur Wadhwani

- 60. Example 2 Courtesy of Dr. Chandur Wadhwani

- 61. Implant Loss from Retained Cement

- 62. Example 1 Courtesy of Dr. Chandur Wadhwani

- 63. RESIN CEMENT L L Example 2 Courtesy of Dr. John Agar

- 64. This Patient is a DENTIST ! Courtesy of Dr. Franco Audia Example 4

- 65. A Second Problem With Cemented Implant Crowns Is Incomplete Seating • Abutment height is greater than most tooth preparations • Parallelism of abutments is often greater than prepared teeth • Adaptation of crown may be better • Viscosity of cement prevents extrusion of all the excess

- 66. Some Cements Are Nearly Impossible To Completely Remove From Abutment And Implant Surfaces

- 67. 6 experienced clinicians Zinc phosphate, GI, Resin 1.5 – 3.0 mm subgingival Courtesy of Dr. John Agar

- 68. Type of Cement and Amount Retained

- 69. Instrument and Amount of Retained Resin Cement (Panavia)

- 70. Radiographic Density of Cements • Measured potential to be detected on radiographs if cement is left behind (tested 1 and 2 mm thicknesses) • Only Zn containing cements (TempBond & Fleck’s ZnPO4) were detected at 1 mm • GI (RelyX Luting), Resin (RelyX Unicem), and Improv cements were only detected when thickness was > 2 mm Wadhwani, J Prosthet Dent 2010;103:295-302

- 71. Cementation Guidelines • Abutment should have texture (not be highly polished)

- 72. Cementation Recommendations • Use a provisional cement (ZOE) such as temp- bond unless the retention is compromised by a short abutment, a very tapered abutment, or the screw access hole eliminates retentive surface(s)

- 73. Cementation Recommendations When retention is compromised, use zinc phosphate cement

- 74. Cementation Recommendations • Loosened after 2 months with ZOE

- 75. Minimizing Cement Extrusion When Cementing Crowns • Express poly (vinyl siloxane) impression material inside the crown to make a PVS die • Mix cement and place it inside the crown, seat the crown on the PVS die to express the excess cement • Quickly remove crown from PVS die and seat in the mouth Wadhwani, J Prosthet Dent 2009;102:57-58 Caudry, J Prosthet Dent 2009;102:130-131

- 76. Thank You For Your Attention Charles J. Goodacre, DDS, MSD Professor of Restorative Dentistry Loma Linda University School of Dentistry

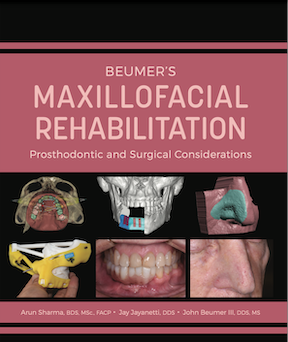

- 77. v Visit ffofr.org for hundreds of additional lectures on Complete Dentures, Implant Dentistry, Removable Partial Dentures, Esthetic Dentistry and Maxillofacial Prosthetics. v The lectures are free. v Our objective is to create the best and most comprehensive online programs of instruction in Prosthodontics